That means they are not yet finished:

More like 4 inch diameter PVC pipes with a 1 inch steel pipe through the center (we hope) prior to filling with concrete. It’s an idea I’ve had for a while to make a printing press for intaglio plates. May or may not work…

In this step, both cylinders are filled with concrete and allowed to harden. Some plywood end stock was fitted to each end to help set the steel pipe through the center. Whatever happens next will not happen until next year. See you then!

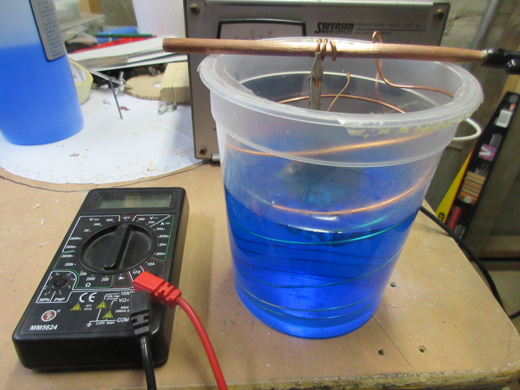

And in another corner, some project involving electro-forming:

This project is about electrochemistry, copper anodes and sulfuric acid; the idea is to coat various non-conductive surfaces with metal by a process called Electro-Forming. It’s how bronzed baby shoes were made (if you remember those.)

This is an example of a non-conductive surface that could be coated with metal. Maybe they could be made into earrings? After they are dried, the surface is coated with lacquer and, depending on a number of conditions I haven’t quite worked out yet, the surface is made conductive and then electro-plated. At this moment I have not perfected the method.

Naturally I have a constant source of insects (dead or alive) to choose from. The coating process seems like it may require some intervals to properly get the job done with insects. The initial coating requires a freshly deceased subject such that the legs and antennae can be manipulated without breaking off.

Or something like that. Sufficient time to dry out is important at this stage. I’m giving this guy at least a month to dry completely before I do the final coating.

About this time there was a little diversion to make a few holiday projects with the Hub Crew at the Harmony Library. Hope to get back with more projects next year!